TYPES OF SYRINGES

Syringes are divided into different types.

There are Luer (Luer) and Luer lock (Luer Lock), syringes with catheter tips (Zhanet) and insulin syringes. Each type of syringe has its own characteristics and is used in different situations. Luer syringes are made entirely of glass and are distinguished by having a tip cone diameter of 4 mm. This is larger than the diameter of metal syringes, which is 2.75 mm.

Luer syringes, in turn, are divided into Luer Slip or simply Luer, and Luer Lock.

With Luer Slip, the needle is attached to the syringe, which is a quick and easy way to attach the needle. This is the standard for syringes with a volume of 1-100 ml. Such a tool is usually cheaper. It is usually used for quick injections. Needles can sometimes pop out, which is why some medical professionals prefer to use a Luer-lock syringe. They are called Luer lock.

Luer Lock syringes provide a more secure connection. Luer locks require a needle to be threaded and locked into place. This helps prevent the needle from accidentally slipping and falling.

This type of instrument is also called a screw-on syringe due to its screw-type connector. What does this mean in practice? The screw connector allows you to screw the needle into the syringe, rather than push it in, as is the case with conventional syringes. Yes, this process becomes more complicated and takes a little longer, but in some cases it is worth it. The fact is that in this case the needle is guaranteed not to fly off the syringe. This may be important if the injection is given to a child or, for example, an animal. When making sudden movements, the needle quite often flies off. This syringe is also appreciated by cosmetologists. In any situation, this syringe will not allow you to lose a single drop of the drug, which is especially valuable when working with expensive cosmetic procedures.

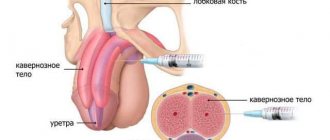

The second type of syringes is Janet (catheter-type). Janet-type syringes have an off-center tip and are often used for injections into superficial veins or arteries. With their help, cavities and catheters (gastric and urological) are washed, they are also used for insertion into an enteral feeding tube. They are distinguished by a ring at the end of the rod; such syringes can be used in urology, gynecology, otorhinolaryngology and surgery.

Insulin syringes usually come with a needle attached. A short, thin needle helps prevent injection pain and bruising. The barrel of an insulin syringe is long and thin, marked in units of insulin.

Depending on the amount of use, syringes can only be disposable or reusable. Single-use plastic instruments with a stainless steel needle. Reusable instruments are usually glass. As, for example, Janet syringes for repeated use. These also include various pen syringes and pistols.

Cosmetic needles for mesotherapy - classification and types

There are also different types of needles used in mesotherapy salons. Let's look at the main ones.

Nanoneedles

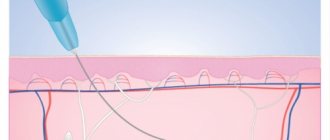

Ultra-thin needles, used mainly to create a lifting effect and general tightening of the skin. They help awaken internal metabolic processes and accelerate the regeneration of epithelial cells.

Characteristics of nanoneedles:

- Minimum wall thickness. Due to this, they are able to carry out even the most viscous preparations;

- Small diameter. It is only 0.24 mm;

- Minimal tissue damage during drug administration;

- Manufacturing material – steel. Due to this, they are quite inexpensive and sharp.

However, keep in mind that due to the steel coating they are short-lived, which is why reusable needles only last 8-12 uses.

SIT needles

The most atraumatic needles are 1.5-2 mm long. They pierce the skin to a depth of only 1 mm, due to which it is not severely damaged and quickly recovers after mesotherapy.

At the base of the needles there are small vacuum caps that control the depth of skin puncture and help reduce pain.

What is the difference between mesotherapy and regular mesotherapy?

It is impossible to use ordinary medical needles for mesotherapy, since they act more aggressively on the skin, leaving noticeable marks on it after the introduction of the meso-cocktail.

In addition, the syringes for the technique also differ, since they have additional rubber protection, ensuring safe administration of the composition.

Syringe size

The size of the syringe depends on how much liquid you need to use and the injection you will be giving. Syringes are marked in cubic centimeters (cc) and milliliters (ml) and are marked on the barrel of the syringe.

The graduation on an insulin syringe shows the number of units it holds and is not always displayed in cubes or ml. For example, 1/4 ml insulin syringes hold approximately 25 units, 1/3 ml - approximately 30 ml. A ½ ml insulin syringe will hold approximately 50 units, a 1 ml syringe will hold approximately 100 units.

By design, syringes can be two-component. This means that they consist of a cylinder and a piston. Two-component syringes are produced in 2 ml, 5 ml, 10 ml or 20 ml volumes.

Three-component syringes also have a plunger in their design. This is a seal to ensure that the piston slides smoothly along the cylinder. Janet syringes are three-component.

According to the volume of the cylinder, syringes are:

- up to 1 ml. Such instruments are needed for administering drugs to take intradermal samples during vaccinations.

- 2-22 ml. A syringe of this volume is used for subcutaneous intramuscular and intravenous injections.

- 30-100 ml. Large-volume syringes are used to rinse cavities and administer nutrient solutions.

If we talk about the intended use, then, as mentioned above, Janet syringes are used for rinsing cavities and tube feeding, Luer syringes are used for injections. There are also special types of syringes, for example, a syringe for intralaryngeal infusions and washing of the tonsils; it is included in the otolaryngologist’s kit.

An integral part of working with a syringe is the needle.

Needles are marked differently than syringes. The package will have a number, then a "G" and then another number.

Recommendations for selecting needles

The correct choice of injection device for introducing an anti-aging composition is the key to reducing side effects from the procedure. The difference between a needle intended for mesotherapy and a regular one is its special cut. A cut at an angle of 30 degrees (Labelle needle) is considered correct. This ensures high-quality introduction of components to the required level.

The size of the needle bar depends on:

- areas of injection exposure;

- composition viscosity;

- patient's pain threshold.

For the most part, medical instruments with a thickness of 0.2 to 0.4 mm are used. Sensitive areas around the eyes or lips suggest choosing a mesotherapy needle with a limiter (sit), provided that the cosmetologist guarantees that the procedure is carried out correctly.

For low skin sensitivity, it is advisable to use an insulin syringe as a consumable. It allows manipulation on both the face and body.

If there is a predisposition to the formation of hematomas, thinner needles or a syringe with a nano rod are used. This method is also used for high pain thresholds.

Sharpening the needle point is also important. When treating a large area of skin, the cosmetologist is obliged to change used materials in a timely manner in order to prevent additional mechanical damage to the epidermis.

Since the injection method of rejuvenation requires many injections, situations where the needle may jump off the syringe are possible. To avoid this, it is necessary to select a high-quality fastening of the metal rod. The fastener in the form of a lock, where the plastic base is built directly into the syringe, has proven itself well.

Determining the needle size

The first number before the letter G indicates the gauge of the needle. The higher this number, the thinner the needle. The second number indicates the length of the needle.

What do calibers say?

So, if you need to inject a small amount of medication, it will usually be less painful to use a thin, high-gauge needle. A fine needle may also be needed if the veins are smaller than average.

For larger quantities of medication, a wider, lower-gauge needle is often the best choice. Although it may be more painful, the injection will be faster with a wide, low-gauge needle than with a thin, high-gauge needle.

Features of the standard

Color codes are established for disposable sterile needles with a diameter of 0.3-3.4 mm, which are intended for intravenous, subcutaneous, intramuscular administration of drugs and blood sampling.

The standard applies to products with thin, extra-thin, normal walls. Needles for mesotherapy procedures are not covered; their outer diameter is smaller. Labeling allows medical personnel and trade organizations to navigate the variety of products. Depending on the manufacturer, colors may vary slightly, but this does not affect the quick search for needles. The color coding of the needles indicates the outer diameter and gauge size.

Color and Size Chart

Although it is possible to determine the size by the color of the injection needles, the user is advised to check the parameters. Domestic encoding standards are similar to international ones. Imported products are marked with the letter G to determine the diameter, which is indicated in inches. The larger the gauge size G, the smaller the diameter.

The rules establish color ranges that are the same for all manufacturers of medical equipment and equipment. The intensity of the yellow-green and blue-gray colors may vary between brands, but any blue needle will be thicker than a brown one.

Needle length

As for needle length, the best choice will depend on the person's size (a small child will need a shorter needle than an adult) as well as where the needle will be inserted.

Some medications are injected directly under the skin, while others must be injected into a muscle.

For subcutaneous injections into the adipose tissue directly under the skin, relatively shallow injections are made; the needle required is small and short with a gauge of 25 to 30.6.

Intramuscular injections go directly into the muscle. The muscle is deeper, so the needle used for intramuscular injections must be thicker and longer. For these injections, consider the amount of fat in the body that the needle must pass through.

Needle classification:

| Needle size (G) | inner d (mm) x needle length (mm) | color according to international classification |

| 30Gx1/2 | 0.3 x 13 mm | yellow |

| 29Gx1/2 | 0.33 x 12 mm | yellow |

| 27Gx1/2 | 0.4 x 13 mm | grey |

| 26Gx1/2 | 0.45 x 13/16 mm | brown |

| 25Gx1 | 0.5 x 25 mm | orange |

| 24Gx1 | 0.55 x 25 mm | violet |

| 23Gx1 | 0.6 x 25 mm | blue |

| 23Gx1 1/2 | 0.6 x 32 mm | blue |

| 22Gx1 1/4 | 0.7 x 32 mm | black |

| 22Gx1 1/2 | 0.7 x 40 mm | black |

| 21Gx1 1/2 | 0.8 x 40 mm | green |

| 20Gx1 1/2 | 0.9 x 40 mm | yellow |

| 19Gx1 1/2 | 1.1 x 40 mm | cream |

| 18Gx1 1/2 | 1.2 x 40 mm | pink |

| 16Gx1 1/2 | 1.6 x 40 mm | white |

The best manufacturers

When choosing high-quality needles for mesotherapy, it is better to pay attention to trusted manufacturers, whose products are often used by specialists in salons.

Let's look at the most popular brands recommended by cosmetologists.

Terumo Neolus

One of the most popular needles, having a minimum wall thickness and a fairly wide diameter. Thanks to this characteristic, they are able to introduce even the most viscous meso-cocktails.

The triangular sharpening of the needle ensures its rapid entry into the skin with minimal damage.

Mesoram

The manufacturer specializes in reusable needles, which can be used for 15-20 sessions. They have multifaceted sharpening and silicone outer protection, due to which they remain sharp for a long time and easily penetrate the skin.

In this case, you can choose any needle size - from 2 to 40 mm, taking into account the density of the skin in the treated area and the problem you want to eliminate.

Meso Relle

The needles of this company are sharpened using laser equipment, which ensures their painless entry into the skin, which ensures minimal damage to the skin.

The needle sizes also vary, ranging from ultra-thin (up to 0.2 mm) to quite dense - 0.45 mm.

How to attach the thread?

It was also necessary to find a way to secure the thread on such an ultra-thin needle. Previously, a hole in the end of the needle was drilled or burned out with a laser, but for a needle with a thickness of only 0.03 mm there are no suitable drills, and the laser will melt the metal. In the end they decided to use the old technique of splitting the back end of the needle in two and clamping the thread between the halves.

was founded in 1949, it manufactured meter needles and other parts. Since the mid-1960s, the company switched to the production of medical equipment. It has previously developed and produced surgical needles with thread in a variety of sizes. In 2008, it was included in the list of 300 active new product creators among small and medium-sized manufacturing companies compiled by the Agency for Small and Medium Enterprises of the Ministry of Economy and Industry as the first company in Japan to produce microsurgery needles. In 2009, it received the Prime Minister's Prize at the All Japan Product Development Competition, and in 2010, the company's plant was inspected by the Emperor of Japan.

Advantages

When assessing the results of contouring using cannulas, the following advantages are noted:

- painless injection of fillers;

- lack of a long recovery period;

- the ability to correct small areas of the skin and large areas of the face, neck, and décolleté;

- absence of ruptures, hematomas, redness, swelling;

- rapid smoothing of pronounced folds and deep wrinkles due to the uniform distribution of the injected substance throughout the tissues.

More than half of employees are women

President Kono Junichi

The Japanese market for surgical needles is worth about 25 billion yen per year. About ten companies, both Japanese and foreign, produce them for Japan. Kono Seisakusho now produces about ten thousand varieties of needles and supplies them to clinics throughout the country. The company's president says the company's specialty is its small size, allowing it to produce many quality products in small batches that large enterprises cannot. The company is capable of doing the entire cycle, from marketing to planning, development and production of products. Production equipment is also often made by the company itself.

About 80% of the company's sales come from surgical needles. The company's main plant specializes in ultra-fine needles and other products that require manual labor, and produces mass products in Joso in Ibaraki Prefecture. The main plant produces products that require precision and concentration, and more than half the employees are women. Many of those who work take their children to kindergarten and arrive by bicycle. They work in silence, away from production noise.

The thorny path to success

Microsurgical needles of different sizes compared to sesame seeds (photo credit: )

These thinnest needles in the world were created in 2004 and were developed over three years.

Kono Junichi, president of the company, said that previously it was believed that such thin needles were not needed, and there were no manufacturers technologically capable of producing them. The reason for their creation was the request of one surgeon at the university medical center, who asked to make thinner needles, after which the company began creating an ultra-thin needle.

The development of needles was fraught with great difficulties. Surgical needles are made of special stainless steel. During the manufacturing process it is stretched, cut, pointed, bent, sharpened, but when it is so thin, it becomes more like cotton fiber than metal. Making the needles required each needle to be shaped by hand under a microscope by an experienced worker. Therefore, company employees have developed original equipment and tools for production.

Injection needles (with a short tip), manufactured by SFM Hospital Products Gmbh, Germany

- the needle point has a triangular sharpening;

- each edge is polished three times with ultrasound;

- the needle is coated three times with silicone. Thanks to this technology, the needle enters the fabric without cutting, but pushing the fibers apart. Silicone coating makes its progress smooth and painless

- The needle cannula is suitable for all syringes with a luer fastening type;

- the color of the cannula corresponds to the size of the needle according to international standards;

- needles are packaged in packs of 100 pieces and transport boxes of 10,000 pieces.

, Germany Disposable sterile needle 0.33 x 8 mm. (29G), Price: 2.30 rub. Disposable sterile needle 0.25 x 5 mm. (31G), Price: 6.00 rub. Also purchased with this product:

- Infusion pumps and syringe dispensers

- Three way faucet

- Extension line for Luer-lock and Luer syringe dispenser

- Three-component syringes with Luer Lock connection

- Alcohol wipes for injections

- Injection sterile adhesive plaster

- Medical hemostatic tourniquets, venous

- Medical pillow, blood collection pillow

- Medical treatment tables

Prospects for foreign sales

Surgical needles with a thickness of less than 0.05 mm are still a niche product, and sales volumes in the domestic market are limited, but with the development of transplantation and reconstructive surgery, demand for them is expected to increase. In addition, microsurgery is being increasingly used not only in developed countries, but also in developing countries in Asia, and this market is gradually expanding. For these reasons, it is taking steps to promote its products abroad.

The company often receives visitors from Thailand, China and other Asian countries. These are the countries where we can expect the medical market to expand. Since 2012, the company has been operating in the Chinese market, expanding its capabilities in the world. The company is also monitoring the needs of Chinese clinics and taking into account the possibility of developing new products in China in the future. The company's president, Kono Junichi, strives to effectively use the manufacturing technology of Crownjun brand ultra-thin needles, which have shown the world its uniqueness.

Company information: Kono Seisakusho KK Address: Soya 2-11-10, Ichikawa-shi, Chiba Prefecture, 272-0832 Representative: Company President Kono Junichi Occupation: development, design, production and sale of medical equipment Number of employees (as of April 2015 city, including subsidiaries): 166 Tel.: (081) 0473-72-3281 Website: https://www.konoseisakusho.jp/jp/index.html

Banner photo: Handcrafting the world's thinnest microsurgery needles Text: Harada Kazuyoshi (Nippon.com Editorial Board) Photos: Kodera Kei

(Original article in Japanese published September 9, 2015)

Types of techniques

When performing a mesoprocedure using the nappage technique (shown in the photo), skin damage is minimized and most of the dermis receptors are activated.

Injections occur with an interval of 3 seconds, while 0.02 - 0.05 ml of the product enters the cells.

There are three types of nappage technique:

- deep;

- surface;

- median.

Deep type

Or, as they also say, infiltration is carried out at the hypodermal level.

This manipulation is mostly used during body mesotherapy, when it is necessary to introduce lipolytic or lymphatic drainage meso-cocktails that ensure the elimination of fat and cellulite.

This method requires a needle measuring about 13 ml. The angle of inclination is 90 degrees, injections are reproduced to a depth of up to 10 mm.

Surface type

When implementing this technique, the product is delivered to the epidermal level. For the most part, this method is practiced for mesotherapy of the décolleté, neck and face. And it has several characteristic features:

- shortened needles (4 mm) are used;

- the product is injected along the massage lines;

- punctures are carried out at a distance of up to 1 cm;

- the injection is reproduced no deeper than 0.5 mm;

- the needle is held with the cut side up.

Using this method, a large number of elements are introduced in addition to those that have a gel-like consistency.

Middle type

With this technique, the active substances enter directly into the dermis, at the papillary or reticular level.

The length between injections is 1.5 – 2 cm. Injections are carried out to a depth of approximately 1.5 mm. The tilt of the needle when working with the face is 45 degrees.

Injections are made along vascular lines or massage lines.

This technique is intended for mesoprocedure of hair, blood vessels, stretch marks, and for smoothing skin texture.

History of creation

The syringe appeared only in 1853. It was created by Alexander Wood and Charles Gabriel Pravaz.

The idea was born when Dr. Wood decided that he wanted to relieve his patients of pain, because in those distant times anesthesia consisted of chloroform or ether. Not all patients tolerated these substances; sometimes deaths occurred, and the “new” morphine was poorly absorbed into the blood.

The doctor decided that the anesthetic works best when the substance gets under the skin. Then he began to develop a new treatment method. The basis was the Pascal injector, which was subsequently improved. It took Wood a couple of years to create the syringe.

The injection syringe appeared later. In 1910, doctors designed a reusable syringe with a metal plunger and a metal needle. It was this instrument that became the prototype of modern syringes with needles.